Currently, the major commercial white light-emitting diode (WLED) is the phosphor converted LED made of the InGaN blue-emitting chip and the Ce3+: Y3Al5O12 (Ce: YAG) yellow phosphor dispersed in organic epoxy resin or silicone. However, the organic binder in high-power WLED may age easily and turn yellow due to the accumulated heat emitted from the chip, which adversely affects the WLED properties such as luminous efficacy and color coordination, and reduces its long-term reliability as well as lifetime.

Therefore, the research and development of novel phosphor material as an alternative for the Ce: YAG/organic blinder one, which is featured with both superior optical performance and high physical-chemical stability, have been highly desired.

Supported by the National Natural Science Foundation of China (NSFC) and Fujian Science and Technology Major Project, Prof. WANG Yuansheng and his co-workers at Fujian Institute of Research on the Structure of Matter(FJIRSM), Chinese Academy of Sciences, made a key technical breakthrough on high-power WLED material.

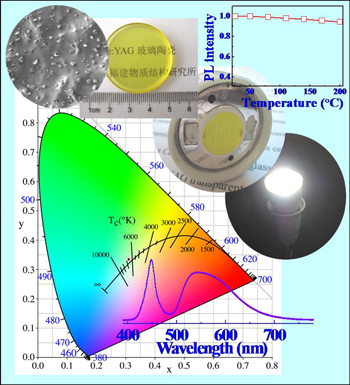

On the basis of disclosing relationships between the component, microstructure and property of the luminescent glass ceramics, the defect structures at the interface between the amorphous phase and crystalline phase are improved, the distribution of YAG micro-crystallites among the glass matrix and the refractive index matching are optimized, then a new-generation Ce: YAG color converter (i.e. glass ceramics) for high-power WLED are innovatively and successfully developed by adopting cheap inorganic raw materials and a simple technical route.

The achieved glass ceramics have good transparency, whose internal luminescent quantum efficiency reaches up to 95%. After assembling with the commercial blue-light LED chips, the device yields a luminous efficacy (LE) of 124 lm/W, a correlated color temperature (CCT) of 6674 K and a color rendering index (CRI) of 70, under an operating current of 350 mA. Impressively, it exhibits admirable heat-resistance and humidity-resistance performances: only 7.6% LE loss is observed and CCT, CRI and color coordination remain unchanged after aging at 150 ◦C for 600 h; and only 5.6% LE degradation is detected after immersing PiG in the boiling water for 24 h.

The related research results have been applied for an international patent and published in an internationally well-known journal Laser & Photonics Reviews(DOI 10.1002/lpor.201300140). It is believed that this result will promote the development of a new-generation long-lifetime illuminating WLED technique.

Schematic illustration of a new generation color converter for high-power white LED: transparent Ce3+: YAG phosphor-in-glass (Image by Prof. WANG’s Group)