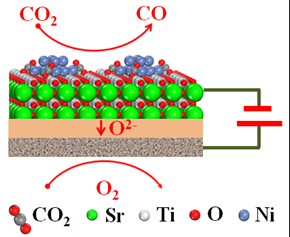

Solid oxide electrolysers can directly electrolyze CO2 to produce fuel, which has attracted a lot of research interests and also demonstrated important practical application in the field of clean energy conversion and utilization.

Redox-stable ceramic electrode can directly perform high temperature electrolysis, and already show excellent high temperature stability and cycling performance; however, the catalytic activity remain a limitation that hinders the electrode performances.

Recently, the research group led by Prof. XIE Kui from the Key Lab of Design & Assembly of Functional Nanostructure, Fujian Institute of Research on the Structure of Matter, Chinese Academy of Sciences, made significant progress in the field of CO2 electrolysis.

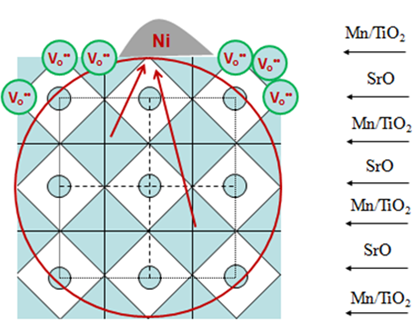

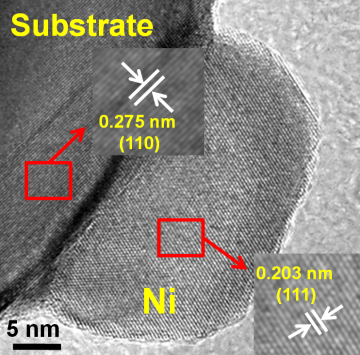

The Ni catalytic particles anchored on the surface of SrTiO3 through controlling nonstoichiometry of the A-site deficient and B-site doped titanate surface, and the doping of redox-active Mn or Cr significantly improve the high temperature chemical adsorption of CO2 molecules by the creation of oxygen vacancies. The coupling of oxygen vacancies with metal catalysts would effectively build active nanostructures to enhance the cathode activity for direct CO2 electrolysis.

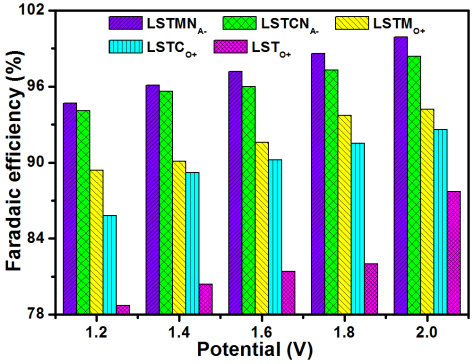

Exceptionally high performance with near 100% Faradic efficiency is demonstrated for direct CO2 electrolysis. Active surface structures not only produce high temperature stability but also substantially enhance redox cycling ability. These titanates are offering the possibility production of active nanostructures in solid oxide electrolyser cells for energy conversion and storage.

The research results were published in Nature Communications entitled “Enhancing CO2electrolysis through synergistic control of non-stoichiometry and doping to tune cathode surface structures”.

Schematic diagram of Ni nanoparticles anchoring on the ceramic electrode surface; the interface state between Ni metal with substrate; the electrocatalytic performance for pure CO2 electrolysis at 800 oC.(Image by Prof. XIE’s group)

Contact:

Prof. XIE Kui

Fujian Institute of Research on the Structure of Matter

Chinese Academy of Sciences

E-mail: kxie@fjirsm.ac.cn.