Porous single crystal monolithic catalytic materials have the advantages of long-range ordered lattice structure,disorderly interconnected pore structure, clear lattice structure, precise chemical composition and clear surface composition, which can construct continuous highly distorted active surface and fine active structure. It is of great significance for the study of surface structure and catalytic mechanism in various practical catalytic reactions.

Recently, the research group led by Prof. XIE Kui from Fujian Institute of Research on the Structure of Matter, Chinese Academy of Sciences , grew porous single-crystalline Mn3O4 and Mn2O3 monoliths at centimeter scale to create well-defined surface structures and confined the atomically dispersed Pt at Mn sites in lattice at the twisted surfaces to construct isolated active sites in the porous single-crystalline architectures.

They demonstrated the significantly enhanced activation of lattice oxygen linked to the isolated Pt ions in lattice in the local structures at the well-defined surfaces. The study was published in CCS Chemistry .

The researchers firstly grew the parent single crystals of (001) Mn2P2O7 and (014) MnCO3, then remove the periodic target atomic P-O or C-O structures using a lattice reconstruction strategy by reconstructing the framework structure of Mn-O single crystal into the mesoporous single crystal.

At high temperatures, the reconstruction of lattice structures in a crystallization process would lead to the formation of interconnected pores. And the lattice shrinking from parent carbonate and phosphates single crystals to oxide single crystals mainly contributed to the formation of porosity and pore structure.

Besides, the researchers confined the isolated Pt at the site of Mn in lattice at the top layer of porous Mn3O4 and Mn2O3 single crystals using atomic layer deposition strategy. The high-sensitive low-energy ion scattering (HS-LEIS) spectra show the successful deposition of Pt at the top layer of porous single crystals.

The Fourier transform of k3-weight of Extended X-Ray Absorption Fine Structure (EXAFS) spectrum for the isolated Pt1/PSC-Mn3O4 shows a radial distribution at ~1.62  for the Pt-O coordination meanwhile the Pt-Pt distribution at ~2-3

for the Pt-O coordination meanwhile the Pt-Pt distribution at ~2-3  is not observed.

is not observed.

The X-ray absorption near edge structure(XANES)measurements confirm that the valence states of isolated Pt species are between the Pt4+ and Pt0 at the top layer of PSC-Mn3O4.The coordination structures of the PtO1.4 and PtO1.5 active sites are clarified by the comparative analysis of the Cs- HRTEM(High Resolution Transmission Electron Microscope)image and lattice structures

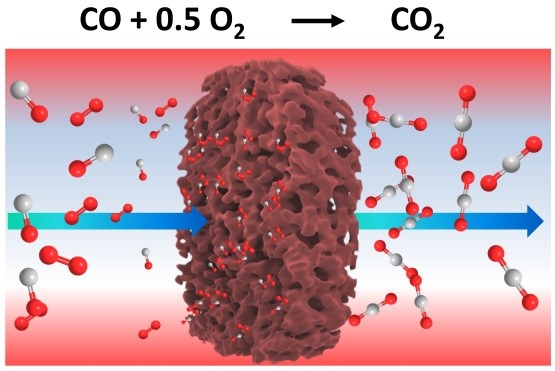

By loading Pt, isolated and fine structure active centers of PtO1.5 and PtO1.4 were constructed in the surface of crystal lattice. In the local structure, the lattice oxygen connected with Pt ions is easier to be activated, and the surface oxygen exchange coefficient is increased by ~ 7-8 times. They show the complete CO oxidation with air at 65°C without degradation being observed even after the operation of 300 hours using the porous single-crystalline monoliths.

This study provides an effective strategy to modulate the selectivity of CO2 electroreduction by designing single types of active sites and stabilizing key intermediates with hydrogen bond and improve the current density via using conductive framework materials.

Illustration of the Research (Image by Prof. XIE’s group)

Contact:

Prof. XIE Kui

Fujian Institute of Research on the Structure of Matter

Chinese Academy of Sciences

Email: kxie@fjirsm.ac.cn