Composites are widely used in different industries due to their ultra-high specific strength and specific modulus. Natural fibers are considered as an alternative to synthetic fibers due to their advantages such as lightweight, biodegradability, low cost, low energy consumption, abundant availability. The connection between mechanical properties and age factors has guiding significance for the application of bamboo fiber-reinforced composites (BFRC) in outdoor engineering.

In a study published in Journal of the Mechanical Behavior of Biomedical Materials, Prof. LU Yubin's group from Fujian Institute of Research on the Structure of Matter of the Chinese Academy of Sciences designed two different aging tests and explored the interaction between these two aging tests.

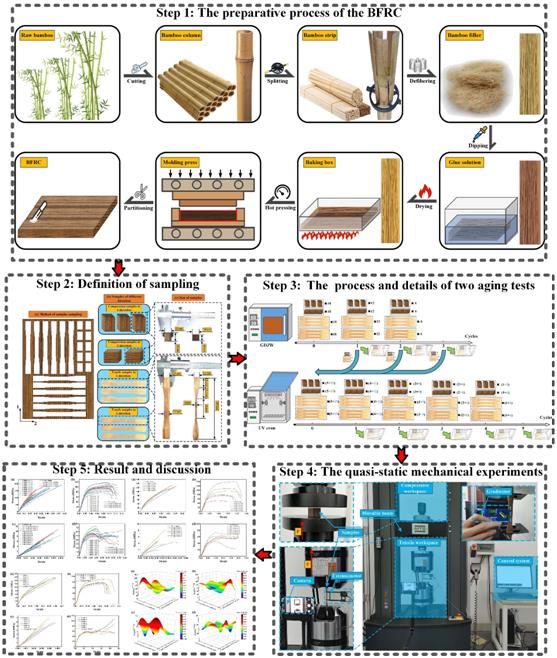

The researchers first obtained bamboo columns by cutting raw bamboo, made the bamboo strips by splitting the bamboo columns with a special knife, and defibered the bamboo strips into coarser bamboo fiber bundles. They focused on extracting bamboo fiber from natural bamboo as a reinforced phase in BFRC and making BFRC sheets by dipping, drying, and hot pressing the coarse bamboo fiber bundles.

Then, the researchers processed the samples into specific specimens for subsequent aging tests and quasi-static mechanical tests. They chose the cold-hot test and the ultraviolet(UV) dry-wet test as representatives of the aging test to account for the natural weathering of raw materials in the open air, and carried out quasi-static experiments to study the mechanical properties of aged BFRC.

Besides, the researchers performed mechanical tests on untreated BFRCS, revealing that the BFRC has significant anisotropy. The tensile strength of BFRC paralleled with the axis of the reinforcing fiber is as high as 148.53 MPa. It is 26.47 times greater than the tensile strength of BFRC perpendicular to the axis of the reinforcing fiber. This anisotropy was found to be closely related to the material preparation process.

After understanding the basic properties of the material, the researchers carried out aging tests and quasi-static mechanical tests on the samples. They found that the aging tests have different effects on the mechanical properties of BFRC in different directions. The scanning electron microscopy (SEM) images showed that the effect of the UV dry-wet test on BFRC is more significant than that of the cold-hot test. The SEM images indicated that cracks occured on the surface of BFRC samples under the UV dry-wet test. The two aging tests had an interactive effect on BFRC, which can reduce the sensitivity of BFRC to a UV dry-wet environment.

This study provides a good reference for predicting the lifetime of BFRC for use in outdoor construction.

Illustration of the research on the mechanical properties of aged BFRC(Image by Prof. LU’s group)

Contact:

Prof. LU Yubin

Fujian Institute of Research on the Structure of Matter

Chinese Academy of Sciences

Email: luyubin@fjirsm.ac.cn