Nature is a master of design, showcasing shapes from intricate hexagonal snowflakes and elegant helices of DNA and galaxies to the radial symmetry of diamonds and the complex contours of leaves. Nature also constructs precise hollow structures, such as protein polyhedra and viral capsids, through efficient bottom-up self-assembly, offering chemists promising strategies for synthesizing complex nanoarchitectures.

In a study published in Chem, Prof. WU Mingyan's research group from the Fujian Institute of Research on the Structure of Matter, Chinese Academy of Sciences, presented a bottom-up self-assembly approach to synthesize a novel pillar-cage fluorinated hybrid porous framework, which exhibits a rare crystalline quasi-Johnson solid J28 structure.

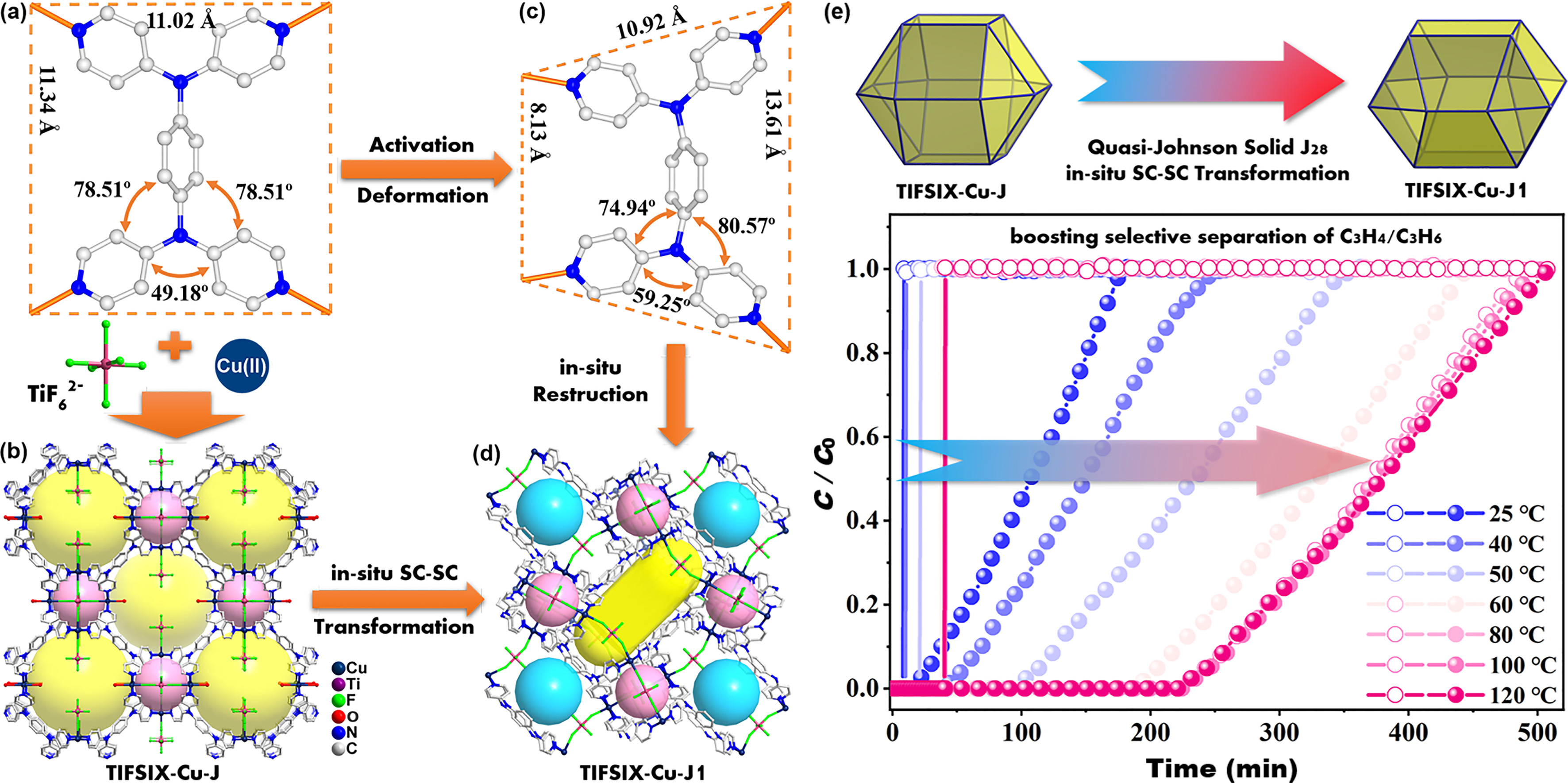

Adsorptive separation process based on porous materials is widely employed in various separation scenarios owing to its mild operating condition and energy-efficient characteristic. A novel pillar-cage fluorinated hybrid porous framework (TIFSIX-Cu-J) featuring quasi-Johnson solid J28 was synthesized by bottom-up self-assembly approach with geometrical elements of quadrangular and isosceles triangles.

The researchers discovered that TIFSIX-Cu-Jundergoes a single-crystal-to-single-crystal (SC-SC) transformation upon in-situ heating activation, during which the J28 cage is restructured to form a new distorted square orthobicupola in the regenerative structure TIFSIX-Cu-J1. The structural changes were elucidated through detailed analysis of the SC-SC transformation and bulk crystalline powder X-ray diffraction.

Importantly, the self-assembly strategy can be applied to synthesize isomorphic crystals, exemplified by SIFSIX-Cu-J (SiF62- as the replaced anionic pillar) and ZrFSIX-Cu-J (ZrF62- as the replaced anionic pillar), can also exhibit in-situ SC-SC structural transformations. These observations underscore the universality of this structural design approach, thereby highlighting the high value of pillar-cage fluorinated hybrid porous materials in both design and application.

Along with the structural transformation, the researchers also found that the adsorption capacity of TIFSIX-Cu-J1 for C3H4 reaches 140.5 cm3∙g-1, and the adsorption amount differences between C3H4 and C3H6 increase from 19.6 to 34.8 cm3∙g-1. Additionally, TIFSIX-Cu-J1 exhibits a higher C3H4/C3H6 (1/99, V/V) IAST selectivity (5.5) than that of TIFSIX-Cu-J (5.0). In-situ breakthrough experiments show that TIFSIX-Cu-J1 packed column can directly yield in a high C3H6 productivity of ca. 368.5 L∙kg-1 at 298 K and 1 bar, which is about twenty times as high as TIFSIX-Cu-J (17.9 L∙kg-1).

Theoretical calculations demonstrate that the more suitable pore surface in the quasi-Johnson solid J28 cavity of TIFSIX-Cu-J1 is beneficial to preferentially capture C3H4 rather than C3H6 and thus boosts selective separation of C3H4/C3H6.

These findings not only provide new insights into systematically design and synthesize innovativepillar-cage fluorinated hybrid porous frameworks but also highlight bottom-up self-assembly as an effective approach for constructing artificial cage-like 3D architectures with selective separation properties in the realm of energy-saving gas purification.

In-situ structural transformation from TIFSIX-Cu-J to TIFSIX-Cu-J1 and the accompanying evolution of separation performance. (Image by Prof. WU’s group)

Contact:

Prof. WU Mingyan

Fujian Institute of Research on the Structure of Matter

Chinese Academy of Sciences

Email: wumy@fjirsm.ac.cn