Lightweight, hierarchically porous elastomeric foams are highly desirable for applications in energy absorption, vibration damping, and flexible sensing. Combining the design freedom of 3D printing with the lightweight nature of foams offers great potential, yet integrating vat photopolymerization 3D printing—known for its high resolution and strong interlayer adhesion—with eco-friendly supercritical fluid foaming has remained challenging due to the high crosslinking density of photocured thermosets, which limits gas diffusion and foamability.

In a study published in Nature Communications, a research team led by Prof. WU Lixin from Fujian Institute of Research on the Structure of Matter, Chinese Academy of Sciences, developed a photocurable resin system that incorporates dynamic hindered urea bonds into a polyurethane acrylate matrix, combined with an amine-based curing agent.

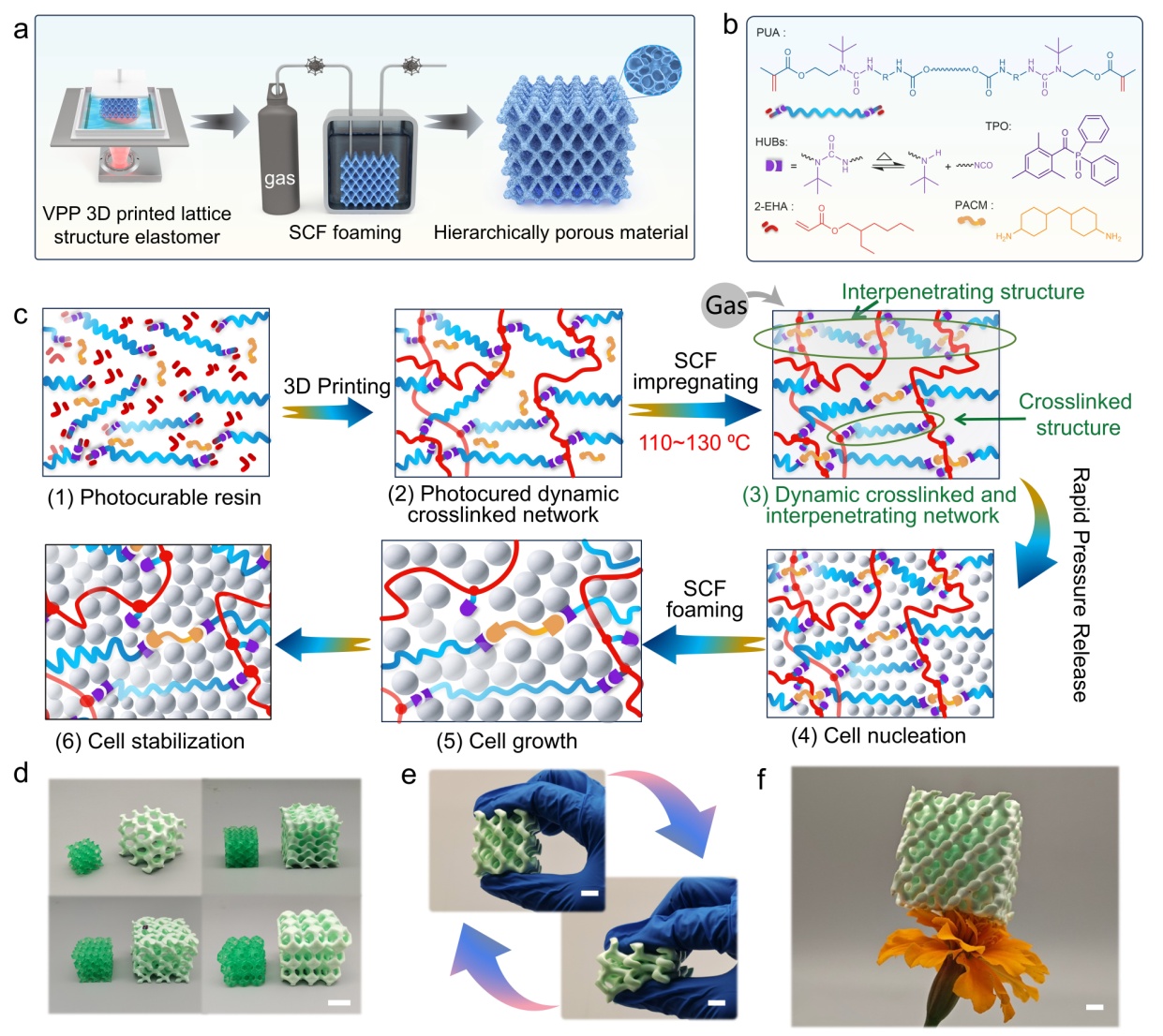

The researchers synthesized a polyurethane acrylate oligomer containing dynamic hindered urea bonds and mixed it with varying amounts of 4,4'-methylenebis(cyclohexylamine) (PACM). During vat photopolymerization 3D printing, the resin forms a dynamically crosslinked network.

Subsequent thermal treatment during supercritical fluid foaming triggers the dissociation of hindered urea bonds, which then react with PACM to generate high-molecular-weight polyurethane/polyurea chains. This process creates a dynamically crosslinked-interpenetrating network that reduces overall crosslinking density, enhances gas solubility, and enables uniform microcellular foaming.

The resulting elastomeric foam exhibited a uniform, crack-free microcellular structure, achieving a high tensile strength of 5.5 MPa and an elongation at break of 510.8%. It also demonstrates exceptional resilience, with a drop ball rebound rate of 67.5% and only 1.7% residual strain after cyclic compression.

Remarkably, the foam is fully recyclable: after hot-pressing, the reprocessed elastomer retains a tensile strength of 8.9 MPa and an elongation of 965.5%, and can be re-foamed multiple times without significant property loss.

The researchers presented a sustainable and versatile route to fabricate high-performance, recyclable hierarchically porous elastomers by seamlessly integrating vat photopolymerization 3D printing with supercritical fluid foaming.

This study provides a generalizable network-engineering strategy for designing advanced lightweight materials with tailored mechanical properties and closed-loop recyclability.

Fabrication of the 3D-printed elastomeric foam with dynamically crosslinked-interpenetrating network (Image by Prof. WU's group)

Contact:

Prof. WU Lixin

Fujian Institute of Research on the Structure of Matter

Chinese Academy of Sciences

Email: lxwu@fjirsm.ac.cn